Table of Contents

The engines are used all over the world for different applications. The internal combustion engine is one of the most commonly used types of engines. In the IC engine, the fuel combustion process occurs inside the engine. The working and design of the IC engine are very different than the EC engine. This article describes the internal combustion engine working, components, types, and applications.

What is Internal Combustion Engine?

An engine in which the fuel combustion process takes place inside the engine cylinder is known as an Internal combustion engine (ICE or IC engine).

The IC engine has the capability to use gasoline, diesel fuel, hydrogen, methane, and propane gas fuel as a working fluid.

The internal combustion engine works by compressing a mixture of air and fuel in the engine cylinder. The fuel is typically gasoline or diesel. The compressed air-fuel mixture is then ignited either through a spark plug or by compression, resulting in a controlled explosion.

When the air-fuel mixture is combusted inside the combustion chamber, then a high pressure and temperature force is produced that acts on the engine piston to generate useful work. As the force acts on the piston, the piston moves forward and backward, which converts the chemical energy of fuel into mechanical energy (power) and moves the vehicle.

An internal combustion engine has the capability to supply 10W power at 20×103 kW. The electrical output of IC is 1000W, and the heating output is approx. 2500W.

Most IC engines are designed for vehicle applications and require an output of approximately 102kW.

An IC engine has greater thermal efficiency than an EC engine. The thermal efficiency of the internal combustion engine is from 35% to 45%.

The petrol engine, diesel engine, two-stroke engine, four-stroke engine, CI engine, and SI engine are examples of internal combustion engine.

The internal combustion engines are most commonly used in motorcycles, buses, vans, trucks, tractors, hybrid cars, and generators.

Working of Internal Combustion Engine

In an IC engine, the fuel combustion takes place inside the engine. As the combustion process takes place, the engine converts the thermal energy of the fuel into rotatory motion. The IC engine has a crankshaft, camshaft, reciprocating piston, and a fixed cylinder. An IC engine works in the following way:

- Suction Stroke:First of all, the engine sucks air from the environment into the compression cylinder.

- Compression Stroke:After the suction stroke, the reciprocating piston inside the compression cylinder compresses the air pressure and temperature. The piston compresses the air up to such high temperature that when the fuel pump injects fuel and mixes fuel with the compressed air, the air-fuel mixture ignites itself and generates power.

- Expansion/Power Stroke: The expansion stroke starts after the combustion process. In this stroke, the combusted air-fuel mixture passes through an expansion valve which expands the mixture. As the air-fuel mixture expands, it forces the piston to move up and down. The movement of the piston moves the crankshaft, which further moves the wheels of the vehicle.

- Exhaust Stroke:In this stroke, the exhaust gases are expelled from theengine cylinder. When the exhaust gases are expelled, then new air is introduced, and the whole cycle repeats.

Types of Internal Combustion Engines

The internal combustion engines have the following major types:

- According to Number of Strokes

- Two-stroke Engine

- Four-stroke Engine

- Five-stroke Engine

- Six-stroke Engine

- Fuel Used

- Petrol Engine

- Diesel Engine

- Bi-fuel Engine

- Nature of Operating Cycle

- Otto Cycle

- Diesel Cycle

- Dual Cycle

- Methods Of Cooling

- Air Cooled Engine

- Water Cooled Engine

- Design Of the Engine

- Reciprocating Engine

- Wankel Engine

- Field Of Application

- Aero Engine

- Portable Engine

- Automobile Engine

- Stationary Engine

- Method Of Ignition

- Compression-Ignition Engine

- Spark-ignition Engine

- Arrangement Of the Engine Cylinder

- W Engine

- Horizontal Engine

- Opposed Piston Engine

- X Engine

- In-Line Engine

- Vertical Engine

- V-type Engine

- Radial Engine

1) According to the Ignition

The IC engine has the following two types according to the ignition process:

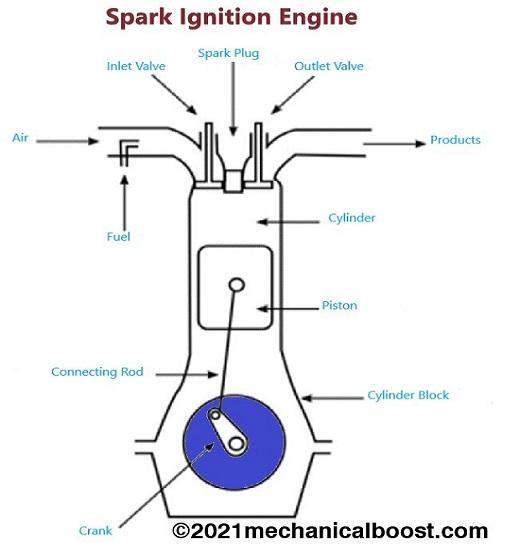

1) Spark Ignition (SI) Engine

Spark ignition engine is one of the most common types of IC engine. These engines are also known as gasoline engines or petrol engines.

The working of the SI engine is very different than the CI engine. This engine contains a carburetor, spark plug, fuel inject, inlet & outlet valves, reciprocating piston, connecting rod, and crankshaft.

In a SI engine, firstly, the carburetor mixes air and fuel then sends this mixture to the compression cylinder. The piston compresses the air-fuel mixture and increases the temperature of the mixture.

When the piston compresses the mixture up to the desired temperature and pressure, a spark plug generates a spark and ignites the mixture. During the power stroke, the expansion of the combusted mixture pushes the piston outward and generates power to move the vehicle.

2) Compression Ignition (CI) Engine

An engine in which the air-fuel combustion occurs due to high compression of the air is known as a compression-ignition (CI) engine. The CI engine doesn’t require a spark plug and carburetor.

In this internal combustion engine, the air draws inside the compression chamber, and then a piston compresses it up to the desired level. After compression, a fuel injector injects fuel inside the combustion chamber. When the fuel touches the highly compressed air, it ignites itself due to the high temperature of the compressed air and generates power.

2) Types According to the Operating Cycle

The internal combustion engine has the following types according to the operating cycle:

1) Otto Cycle Engine

An engine that works on the Otto cycle is known as the Otto cycle engine. The Otto cycle is most commonly used in Petrol or SI engines. This cycle completes a power cycle in four strokes of the piston.

In this cycle, the volume of the air-fuel mixture doesn’t change during compression and exhaust strokes, while enthalpy remains constant during the intake and power strokes. These engines are less powerful than the diesel cycle engine.

Read Also: Working of Otto Cycle

2) Diesel Cycle Engine

An engine that works on the diesel cycle is known as a diesel engine. The diesel engines are most commonly used in heavy vehicles like buses, vans, marine ships, and tractors.

In a diesel cycle, the power stroke takes place at constant pressure. It has less efficiency than the otto cycle for the same compression ratio. The efficiency of the diesel cycle increases by lowering the cut-off. However, it has more compression ratio than the otto cycle.

Read Also: Working of Diesel Cycle

3) Dual Cycle Engine

The combination of the diesel cycle and otto cycle is known as a dual cycle. This engine requires more for the combustion of the fuel. It needs a very small installation area than the diesel cycle engine.

Dual cycle engine completes a power cycle in the following steps:

- Isentropic compression (1 to 2): In this process, the engine piston compresses the gas at constant enthalpy. During this process, the pressure and temperature of the gas increase while the volume reduces.

- Isochoric compression(ignition phase): Line 2 to 3 of the above graph represents this process. During this phase, the piston further compresses the gas at a constant volume. As the gas compression reaches up to a specific level, it ignites and generates power. During this process, the pressure, temperature, and enthalpy increase while the volume remains constant.

- Isobaric expansion(power stroke): Line 3 to 4 represents this phase. In this phase, the ignition of the gas generates power which is used to move the piston. During this phase, the pressure of the gas remains constant while temperature, volume, and enthalpy increase.

- Isentropic expansion(power stroke): Line 4 to 5 represents this phase. In this phase, the combusted gas passes via an expansion valve where it expands and works on the piston. This force of the gas helps the piston to move forward and backward. The piston movement rotates the crankshaft, which further turns the vehicle wheel. During this process, the enthalpy remains constant.

- Exhaust Stroke: Line 5 to 1 represents this process. In this phase, the waste gases are expelled from the combustion chamber to the environment.

3) Types According to the Cylinder Arrangement

1) Horizontally Opposed Engine

The cylinders of this engine are located in two groups on each side of a single crankshaft. This means that both cylinders connect with the same crankshaft. The horizontally opposed IC engine is also known as a boxer engine or Flat engine.

2) Vertical Cylinder Engine

In the vertical engine, the piston moves vertically inside the compression cylinder. This piston moves up and down in the cylinder, and the crankshaft installs below the cylinder.

3) V-type Engine

In the V-type engines, the cylinders are arranged diagonally. These cylinders install in such a way that they make a “V-shape.” The angle between the cylinders diverges from 60 degrees to 90 degrees.

This design of IC engine usually uses an even number of cylinders. These types of internal combustion engines are most commonly used on high-end cars and high-end sports bikes.

4) Radial Engine

The radial engine is a reciprocating internal combustion engine. This engine has an almost similar construction to ” wheel and spokes,” where the cylinder is outside of the central crankcase. It is also known as a “star engine” because of its star shape.

5) In-Line Engine

The cylinders of this engine install in a straight line. Therefore, it is also known as a “straight engine.” The number of cylinders of an in-line engine varies according to the design and requirements. This engine may have between two to eight cylinders. It is a conventional engine. Therefore, it has a simple design.

6) X Engine

When a crankshaft connects two V-engines, an X-engine is formed. The X engine consists of two V-engines. These engines contain their historical importance as they were employed in aircraft during World War II.

7) Opposed Piston Engine

This type of engine has pairs of pistons. These pistons are co-axial and share a single compression cylinder. It doesn’t have a cylinder head. This cylinder contains pistons at both ends.

8) W Engine

Like the V engine, the W engine shares a similar name. In other words, when you view the engine from the front, it looks like the letter W. This type of engine uses multiple banks of cylinders (usually 3 or 4) on a single crankshaft.

4) According To Type of Fuel Used

The internal combustion engines have the following types according to the type of used fuel:

1) Petrol Engine

An engine that generates power due to the combustion of petrol is known as a petrol engine. The petrol engine uses a mixture of air and fuel.

This engine sucks air from the atmosphere, mixes it with fuel, and compresses it. As the compression completes, a spark plug ignites the air-fuel mixture and generates power. These engines have low cost than diesel engines. However, they consume more fuel than diesel engines.

Read Also: Working and types of Petrol Engines

2) Diesel Engine

An engine that generates power due to the combustion of diesel is known as a diesel engine. This engine only compresses the air to generate power. It doesn’t need a spark plug for ignition. In this engine, fuel combustion occurs due to the high compression of the air.

These engines consume low fuel than petrol engines. However, they are more expensive.

Read More: Diesel Engine Working and Types

3) Bi-Fuel Engine

This IC engine is the latest version of the Otto engine. It has the capability to use either gasoline or natural gas. This means that this engine has a dual-fueling system (gasoline system and natural gas system).

5) Types According to Number of Strokes

1) Two-stroke IC Engine

The 2-stroke engine completes a power cycle in just two strokes of the piston. This engine uses just one crankshaft revolution to complete a power cycle. It completes a power more quickly than the four-stroke engine.

Read Also: Working of 2-stroke Engine

2) Four-stroke Engine

The four-stroke engine completes a power cycle after two revolutions of the crankshaft or four strokes of the piston. These engines have high efficiency but low power than the two-stroke engines. The four-stroke engines are most commonly used in trucks, buses, vans, tractors, and many other heavy-duty vehicles.

Read Also: Working of 4-stroke Engine

3) Five-stroke Engine

In 1879, Nicolaus Otto designed a double-expansion engine with two small cylinders alongside a low-pressure large cylinder in which the second expansion of the exhaust stroke occurred.

In 1906, this concept was incorporated into EHV vehicles. In the 21st century, Ilmor succeeded in developing and testing a 5-stroke, dual expansion, IC engine with low SFC (Specific fuel consumption) and high performance.

4) Six-stroke Engine

An engine that completes a power cycle after three revolutions of the crankshaft is known as a six-stroke engine. The 6-stroke engine was invented in 1883.

All four types of 6-stroke engines have conventional cylinders (Crower 6-stroke, Velozeta 6-stroke, Bajulaz 6-stroke, and Griffin 6-stroke) with conventional pistons and make three revolutions of the crankshaft for each stroke.

6) According To the Design of Engine

1) Reciprocating Engine

A reciprocating engine has a piston that moves inside the engine cylinder. This piston has a reciprocating motion.

As the engine combust the air-fuel mixture, a large amount of thermal energy produces. This produced thermal energy forces the piston to reciprocate inside the cylinder.

As the piston gets motion, it transfers this motion to the crankshaft, which transfers the piston’s reciprocating motion into rotary motion and moves the car wheels.

2) Rotary Engine

Main Article: Rotary Wankel Engine

This internal combustion engine uses a rotor instead of a piston. As the fuel combustion generates power, it acts on the rotor, further running the wheels. The Wankel engines do not employ in automobiles because they consume more fuel than the reciprocating engines. These engines also have a high emission rate.

7) According To Cooling

The IC engine has the following types according to the cooling system:

1) Air-Cooled Engine

An engine that uses air to cool the engine is known as an air-cooled engine.

2) Water-Cooled Engine

An engine that uses water for its cooling is known as a water cooled engine.

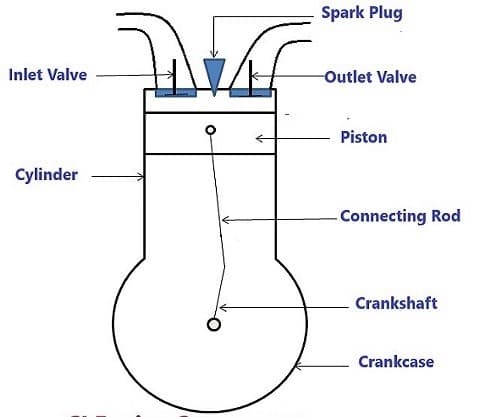

Parts of Internal Combustion Engine

The parts of an internal combustion engine are given below:

- Cylinder

- Cylinder Head

- Piston

- Piston Rings

- Valves

- Connecting Rod

- Crankshaft

- Crankcase

- Flywheel

1) Cylinder

- A cylinder is one of the major parts of the IC engine

- It is manufactured by using steel alloys or aluminum alloys.

- Inside a cylinder, the piston moves forward and backward to transmit energy.

- It will then increase the higher pressure and higher temperature inside the engine’s cylinder

2) Cylinder Head

- It fixed at the upper side of an engine’s cylinder.

- Made of steel alloys or aluminum alloys.

- It manufactures through the process of casting.

- The Copper or the asbestos gasket supplies to the cylinder and then to the cylinder’s head for making it airtight

3) Piston

- The piston is one of the most vital parts of the engine.

- It is most commonly made of aluminum alloys.

- An important function of the piston is to deliver power provided by combusted air-fuel mixture to the crankshaft.

Read More: Piston Working and Construction

4) Piston Rings

- The piston ring is a circular ring made of a typical steel alloy.

- The piston ring points to the grooves of the piston’s circumference.

- 2-sets of sealing rings are supplied, where the uppermost sealing ring can resist combustion gas from leaking into the lower part, and the lower sealing ring can prevent oil from leaking into an engine cylinder.

- It can maintain its elasticity even at high temperatures.

- The piston packing equips with an airtight seal.

5) Valves

- Valves include in the most important components of the internal combustion engine.

- The engine has two valves (Inlet valve and exhaust valve).

- These valves install at the cylinder head.

- The inlet valves utilize to introduce fresh-mixture into the cylinder.

- An exhaust (EGR) valve of the cylinder uses to discharge the exhaust gas from the engine cylinder.

Read Also: Working of EGR valve

6) Connecting Rod

- The crankshaft makes a connection between the piston and the crankshaft.

- The connecting rod’s function is to transfer the power from the piston to the crankshaft.

- It converts the reciprocating motion of the piston into rotary motion and transfers this rotary motion to the crankshaft.

7) Crankshaft

- It makes of special steel alloy.

- The main function of the crankshaft is to take motion by the piston and deliver this motion to the flywheel. The flywheel further uses this rotary motion to turn the vehicle wheel.

8) Crankcase

- Crankcase is made of cast iron.

- It is utilized to control the motion of the inlet and exhaust valves. It is responsible for the proper opening and closing of the inlet valve and the proper supply of the fresh air-fuel mixture.

Read More: Crankcase Working and Parts

9) Flywheel

- The main purpose of the steering wheel is to maintain a constant speed.

- It stores extra energy during energy storage and provides additional energy during the compression stroke.

- It takes rotary motion by the crankshaft and turns the vehicle wheel.

10) Carburetor

- It sucks fresh air from the environment and mixes it with the fuel.

- The carburetor is responsible for properly supplying the air-fuel mixture to the engine cylinder.

Applications of IC Engines

- Automobile: IC engines are most commonly used to power different vehicles, such as motorcycles, buses, trucks, and cars.

- Recreational: Internal combustion engines are used to run jet skis, snowmobiles, and other recreational vehicles.

- Marine: These types of engines are used to power submarines, ships, and boats.

- Industrial: IC engines are used to run compressors, pumps, and other machinery in industries.

- Agriculture: IC engines are used to power combines, tractors, and other farming machinery.

- Power generation: Internal combustion engines are most commonly used in generators to generate electrical power.

- Construction: They are used to run various excavators, bulldozers, and other heavy machines.

- Lawn and garden: These engines power chainsaws, lawnmowers, and other gardening equipment.

- Aircraft: Internal combustion engines are used to run smaller airplanes, drones, and helicopters.

- Small vehicles: They power dirt bikes, motorized scooters, and other small vehicles.

Advantages and Disadvantages of IC Engine

Advantages of Internal Combustion Engines

- These engines have low weight than the EC engines.

- They have small size.

- They start very quickly.

- They have low costs than external combustion engines.

- The IC engines are easy and safe to use.

- Internal combustion engines are compact and can be easily transported. The portability features of these engine make them ideal for use in vehicles and equipment that need to move around.

- They have the ability to use a wide range of fuels, such as biofuels, gasoline, diesel, and natural gas.

Disadvantages of Internal Combustion Engines

- The fuels (such as petrol or diesel) used for IC engines have high costs.

- They have high emission rate than EC engines.

- They are not ideal for large power generation.

- This type of engine requires regular maintenance, such as oil changes, filter replacements, fuel changes, and other upkeep.

- They require proper cooling and lubrication to work efficiently.

- Internal combustion engines have low efficiency, with only around 20% to 30% of the energy from the fuel being transformed into useful work. The remaining energy is lost as heat.

- IC engine is a complex machine that contains multiple rotating parts and need a lot of precision engineering, which can make them more expensive to manufacture and maintain than other types of engines.

Internal Combustion Engine Vs Steam Engine

The main difference between the IC engine ad Steam engine is given below:

| Internal Combustion Engine | Steam Engine |

|---|---|

| In the IC engine, fuel combustion occurs inside the engine cylinder. | In the steam, fuel combustion occurs outside the engine. |

| It has a high working temperature and pressure inside the cylinder. | It has a low working temperature and pressure inside the cylinder. |

| It doesn’t need an additional energy source for combustion. | It requires an additional energy source for combustion. |

| This engine is 35% to 40% efficient. | It is 15%to 20% efficient. |

| It starts immediately. | The steam engine can’t start quickly. It requires some time. |

| It has high thermal efficiency. | It has low thermal efficiency. |

| The IC engine has low weight. | The steam engine has a high weight. |

FAQ Section

What is an IC engine?

An engine in which the fuel combustion process takes place within the engine cylinder is known as an IC engine.

What is the Purpose of Internal Combustion Engine?

The main purpose of the internal combustion engine is to convert the chemical energy of the fuel into mechanical energy (i.e., rotary motion) and run the vehicle.

Why is it called an internal combustion engine?

In the IC engine, the working fuel is combusted inside the engine. Therefore, it is known as an internal combustion engine. There is no need for an external heat source to ignite the fuel.

What are the examples of internal combustion engines?

The petrol engine, diesel engine, Wankel engine, 2-stroke engine, 4-stroke engine, water-cooled engine, air-cooled engine, CI, and SI engines are the most common examples of internal combustion (IC) engines.

Who invented IC engine?

American George Braytondesigned the first commercial liquid-fueled IC engine in 1872. Nicolaus Otto, working with Gottlieb Daimler and Wilhelm Maybach, designed the compressed charge, four-stroke cycle engine in 1876.

What are the types of IC engines?

The internal combustion engine has the following major types:

- Petrol Engine

- Diesel Engine

- Wankel Engine

- Reciprocating Engine

- SI Engine

- CI Engine

- Otto cycle Engine

- Diesel cycle Engine

- Dual cycle Engine

- Air Cool Engine

- Water Cool Engine

- Two-stroke Engine

- Four-stroke Engine

- Five-stroke Engine

- Six-stroke Engine

- Vertical Cylinder Engine

- V-type Engine

- Radial Engine

- In-Line Engine

- X Engine

- W Engine

Read Also

- Different types of Engines

- Different types of Reciprocating Engines

- Working and types of External Combustion Engines

- Stirling Engine Working and Types

- Working of Wankel Engine

- Working and types of Petrol Engines

- Types of Diesel Engines

- How to change Engine Oil